Spoločnosť Tetra Extraction Technology predstavuje novú úroveň extrakcie biologického materiálu. Naša technológia využíva rozpúšťadlo 1,1,1,2-tetrafluóretán, čoho výsledkom sú skutočné full-spectrum extrakty vysokej kvality.

O nás

Tetra Extraction Technology je inovatívna, slovenská výrobno-technologická spoločnosť, ktorá sa zaoberá vývojom a výrobou zariadení na extrakciu hlavne biologických materiálov. Naše portfólio zahŕňa predaj extrakčných zariadení, extrakčné služby na objednávku, predaj vlastných extraktov a hotových výrobkov z extraktov. Tieto si nájdu uplatnenie v segmente výživových doplnkov, produktov osobnej starostlivosti, tiež v gastronómii, či kozmetickom, potravinárskom, liehovarníckom a farmaceutickom priemysle.

Na trh prichádzame s konceptom vysoko účinnej extrakcie, ktorá z hľadiska kvality a efektivity prevyšuje ostatné extrakčné metódy (bután, CO2, etanol, voda…), čo potvrdzujú aj porovnávacie analýzy z akreditovaných laboratórií.

Unikátna technológia založená na rozpúšťadle 1,1,1,2-tetrafluóretán

V našich zariadeniach používame ako rozpúšťadlo 1,1,1,2-tetrafluóretán, ktorý v porovnaní s inými metódami extrakcie prináša výhody, umožňujúce nám stanoviť si vlastné vyššie kvalitatívne štandardy výrobného procesu a výsledných produktov. Hlavnými atribútmi našej technológie sú vysoká efektivita, spoľahlivosť, bezpečnosť, nízka energetická náročnosť a nízke prevádzkové náklady. V rámci výrobného a technologického procesu sú našimi prioritami transparentnosť a ekologický prístup.

Fakty o 1,1,1,2-tetrafluóretáne a jeho použití v našej technológii

- 1,1,1,2-tetrafluóretán je zdravotne nezávadný, nehorľavý, inertný plyn.

- Na rozdiel od iných rozpúšťadiel (bután, CO2, etanol, voda…) nereaguje s extrahovaným materiálom.

- V rámci procesu extrakcie nedochádza k degradácii jednotlivých látok v spracovávanom materiáli, čím sa zvyšuje účinnosť extrakcie.

- 1,1,1,2-tetrafluóretán umožňuje extrahovať čerstvú surovinu a získať tak látky, ktoré procesom sušenia v niektorých prípadoch degradujú alebo sa úplne strácajú.

- 1,1,1,2-tetrafluóretán nepoškodzuje ozónovú vrstvu.

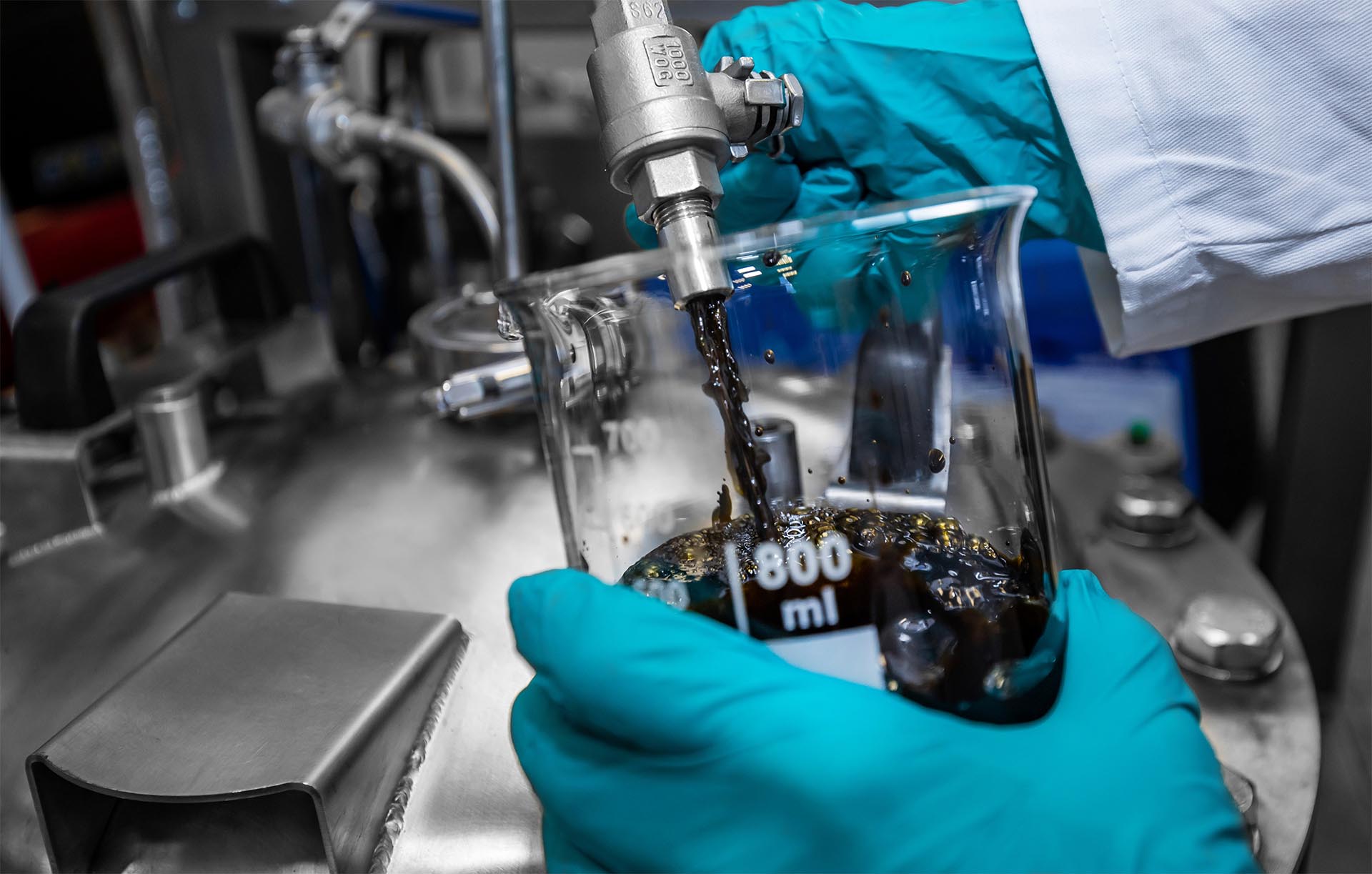

Prémiové extrakty so skutočným plným spektrom

Zariadenia od spoločnosti Tetra Extraction Technology prinášajú zákazníkom extrakty najvyššej kvality so skutočným plným spektrom. Kvalitatívny rozdiel je v senzorických vlastnostiach, širšom spektre účinných látok (fytonutrienty, terpény, flavonoidy, éterické oleje, vosky, etc.) a v ich výrazne vyššej koncentrácii.

Extrakty sú získané v rámci súvislého a komplexného procesu extrakcie jedného druhu materiálu, čím je dosiahnuté skutočné plné spektrum prírodných látok. Pre porovnanie, veľká časť produktov ponúkaných na trhu, dosahuje tzv. „plné spektrum“ a senzorické vlastnosti zmiešaním syntetických aróm a izolátov (z často neznámych zdrojov).

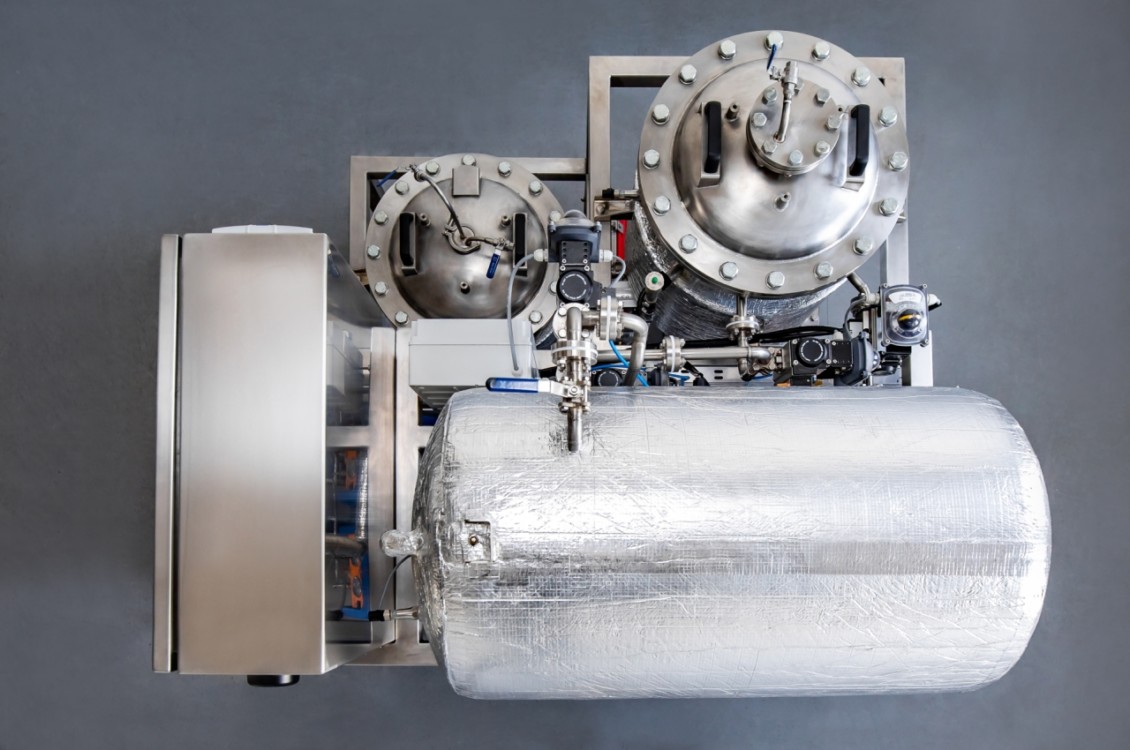

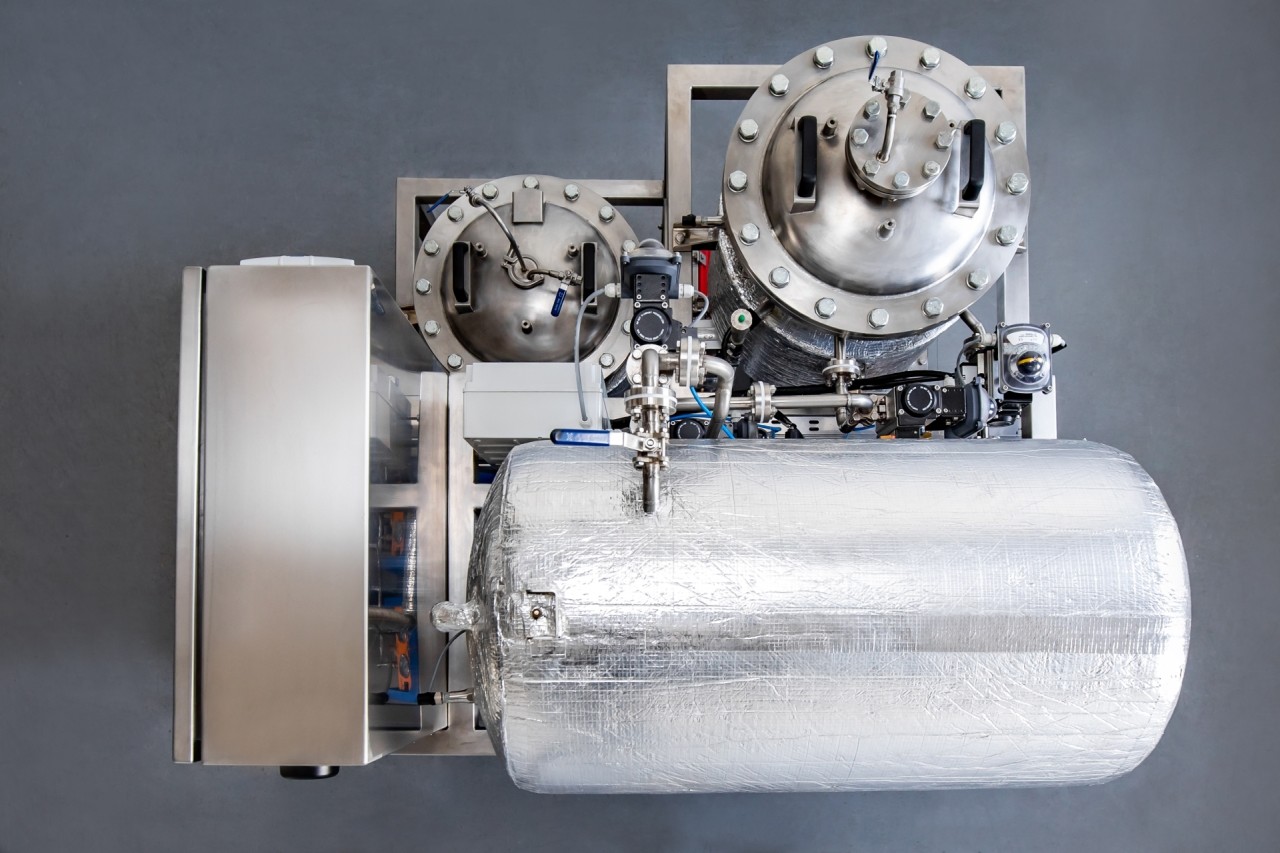

Efektívna prevádzka

Manipulácia a prevoz sú vďaka kompaktným rozmerom a mobilnej koncepcii jednoduché. Energetická nenáročnosť zariadenia umožňuje jeho použitie v akýchkoľvek podmienkach. Nízke nároky na obsluhu bez špeciálnej kvalifikácie s jednoduchým zaškolením umožňujú obsluhovať zariadenie po krátkej dobe takmer každému. Výsledkom extrakcie 1,1,1,2-tetrafluóretánom je vysoká výťažnosť celého procesu a teda efektívne využitie vstupnej suroviny.

Bezpečnosť

Konštrukcia zariadenia a jeho komponentov je certifikovaná, spĺňa príslušné normy a predpisy. Všetky nádoby sú vybavené poistnými ventilmi, tlaky v nich málokedy dosahujú hranicu 10 barov, sú neustále monitorované a v kombinácii s nezávadnosťou a nehorľavosťou 1,1,1,2-tetrafluóretánu je celé zariadenie mimoriadne bezpečné.

Ohľaduplnosť

k prírode

Sme moderná a inovatívna spoločnosť, ktorá pri všetkých svojich aktivitách dbá o ekológiu a znižovanie uhlíkovej stopy. Náš extrakčný proces prebieha v uzavretom okruhu, čím sa minimalizujú straty rozpúšťadla. 1,1,1,2-tetrafluóretán je zdravotne nezávadný, netoxický a preto je možné biomasu, ktorá zostane po extrakcii ako odpad, ďalej spracovať.

Využitie môže nájsť v poľnohospodárstve ako hnojivo, podstielka pre hospodárske zvieratá alebo palivo pre elektrárne na biomasu, preto je možné náš výrobný proces považovať za bezodpadový a ekologicky trvalo udržateľný.

Scroluj dole

Scroluj dole